ABOUT US

IGM MLADOST is one of the largest and most important producers of construction materials in the region, with a tradition of over 112 years. A well-known name on the market, a synonym for quality tiles and blocks for masonry and mezzanine constructions, which, in addition to being present on the domestic market, due to their quality, have found their way to satisfied users in many markets: Macedonia, Bulgaria, Romania, Albania, Bosnia and Herzegovina, Slovakia, Montenegro, Russia, Poland, Germany, France and Belgium.

The company consists of five production facilities in central and southern Serbia.

There are two factories for the production of ceramic tiles in Leskovac and three factories that produce building blocks of different formats in Mala Plana (near Prokuplje), Vlasotince and Stalać.

Since the privatization of the factories, comprehensive investments have been continuously made in all the company’s factories in order to achieve the basic concept of constantly improving quality and assortment in order to respond to the demands and needs of different markets and users. Investments in state-of-the-art technology and equipment, in construction facilities, organization, and modernization of all business processes, marketing, and human resources are particularly significant. The continuous process of investment in the quality of production is also recognized by the end users, so year after year the market for our products expands and the market share increases.

IGM Mladost – Leskovac

Throughout history, "Keramička fabrika Rafajlović, Sokolović i Bejaž", later known as "MLADOST", has become a synonym for superior clay construction material. 🧱

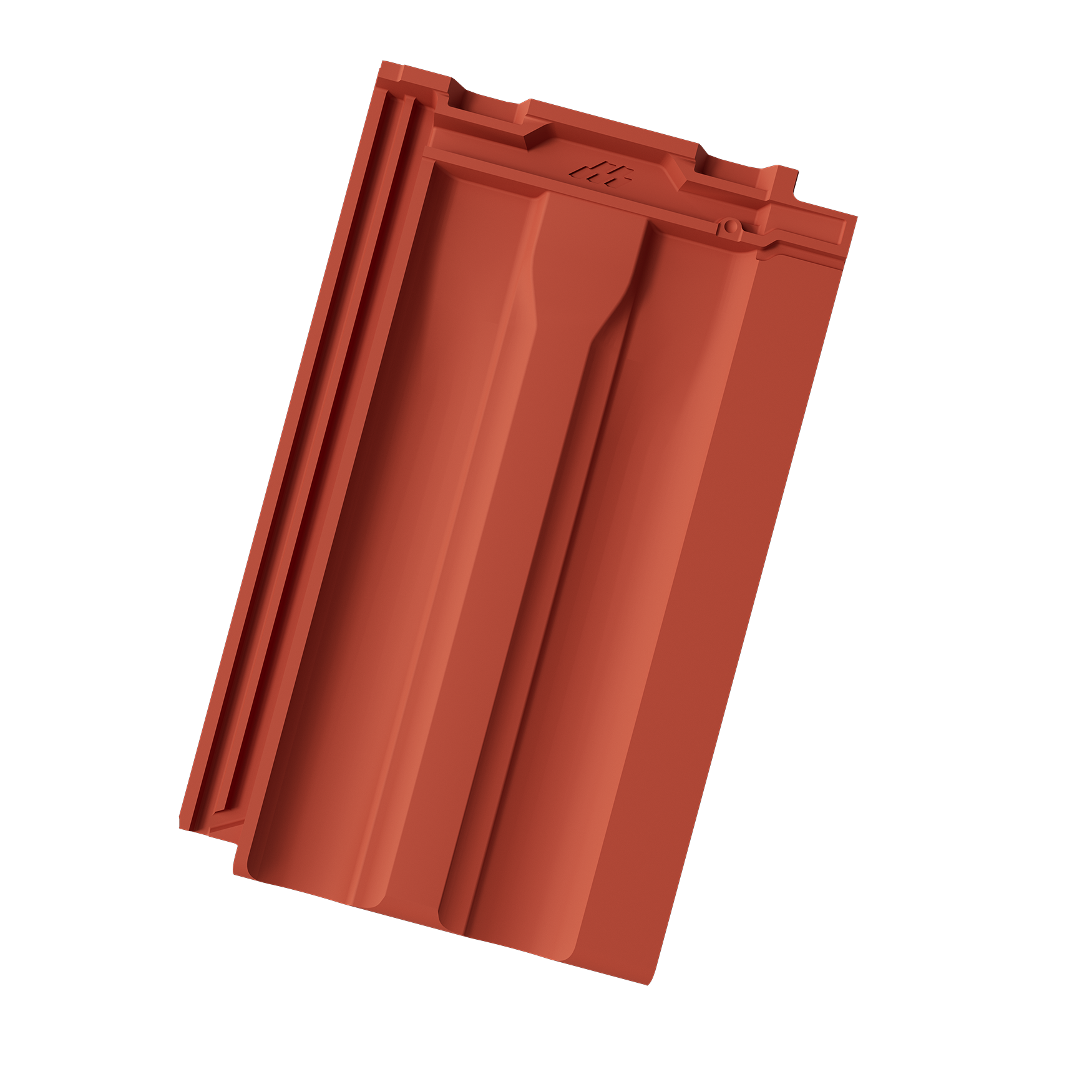

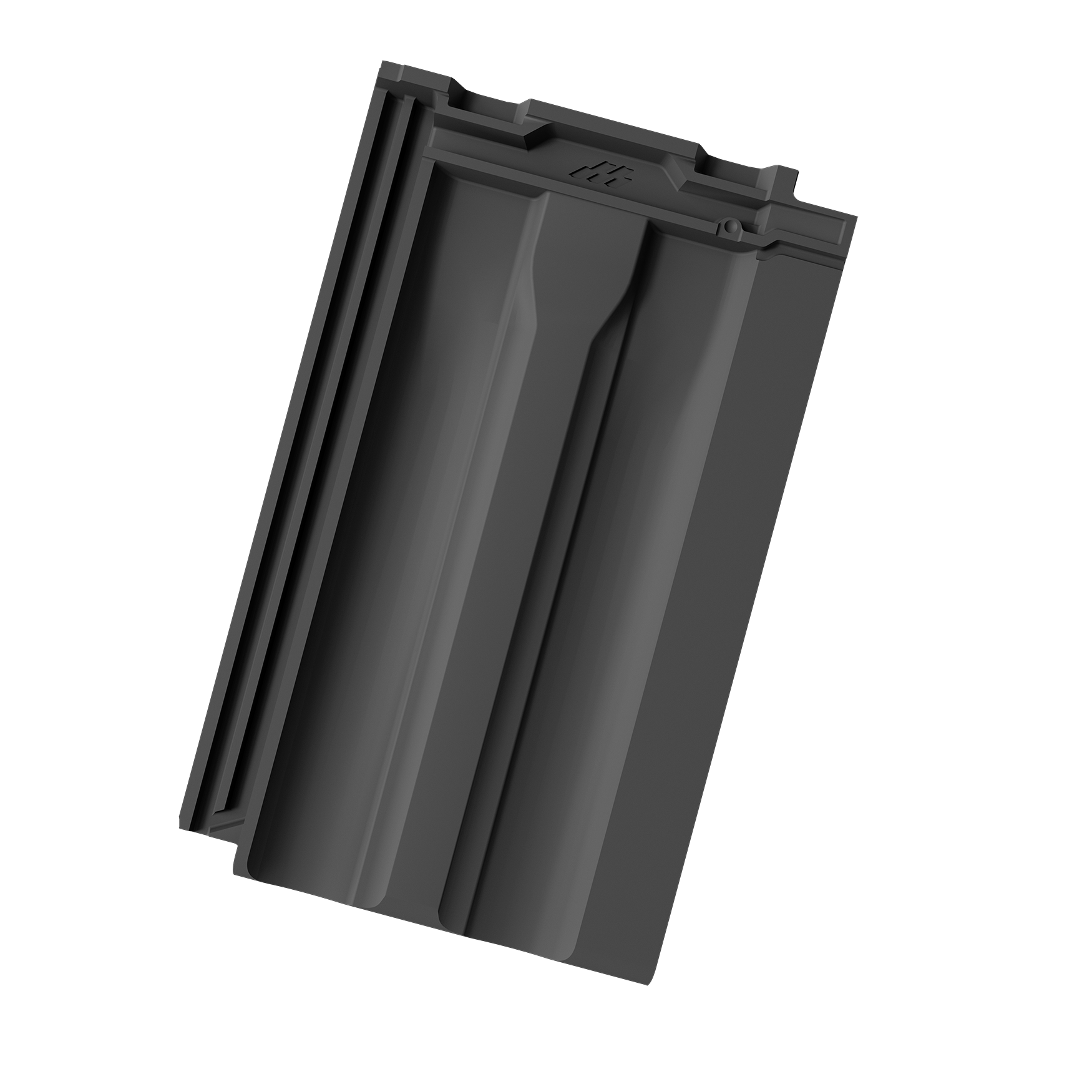

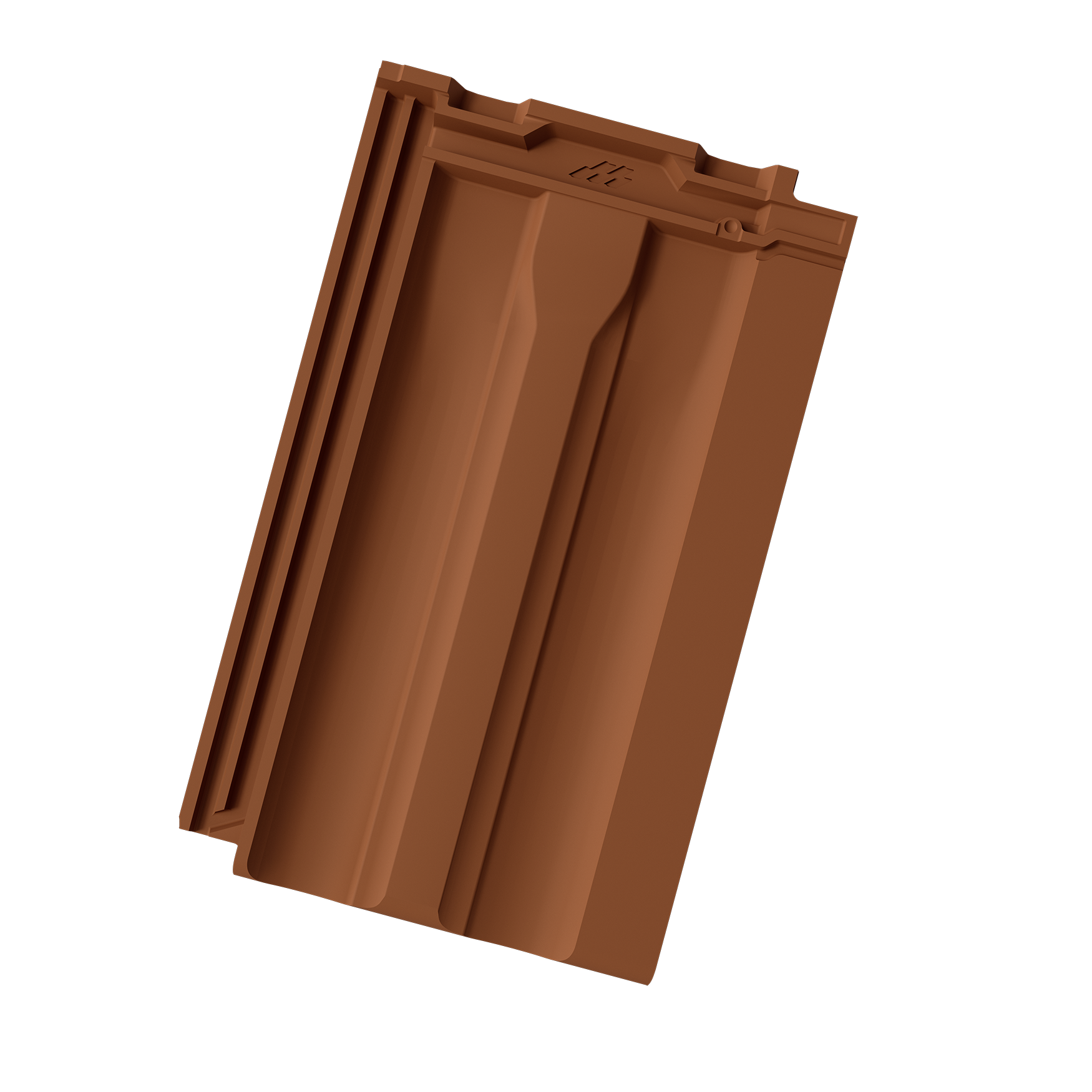

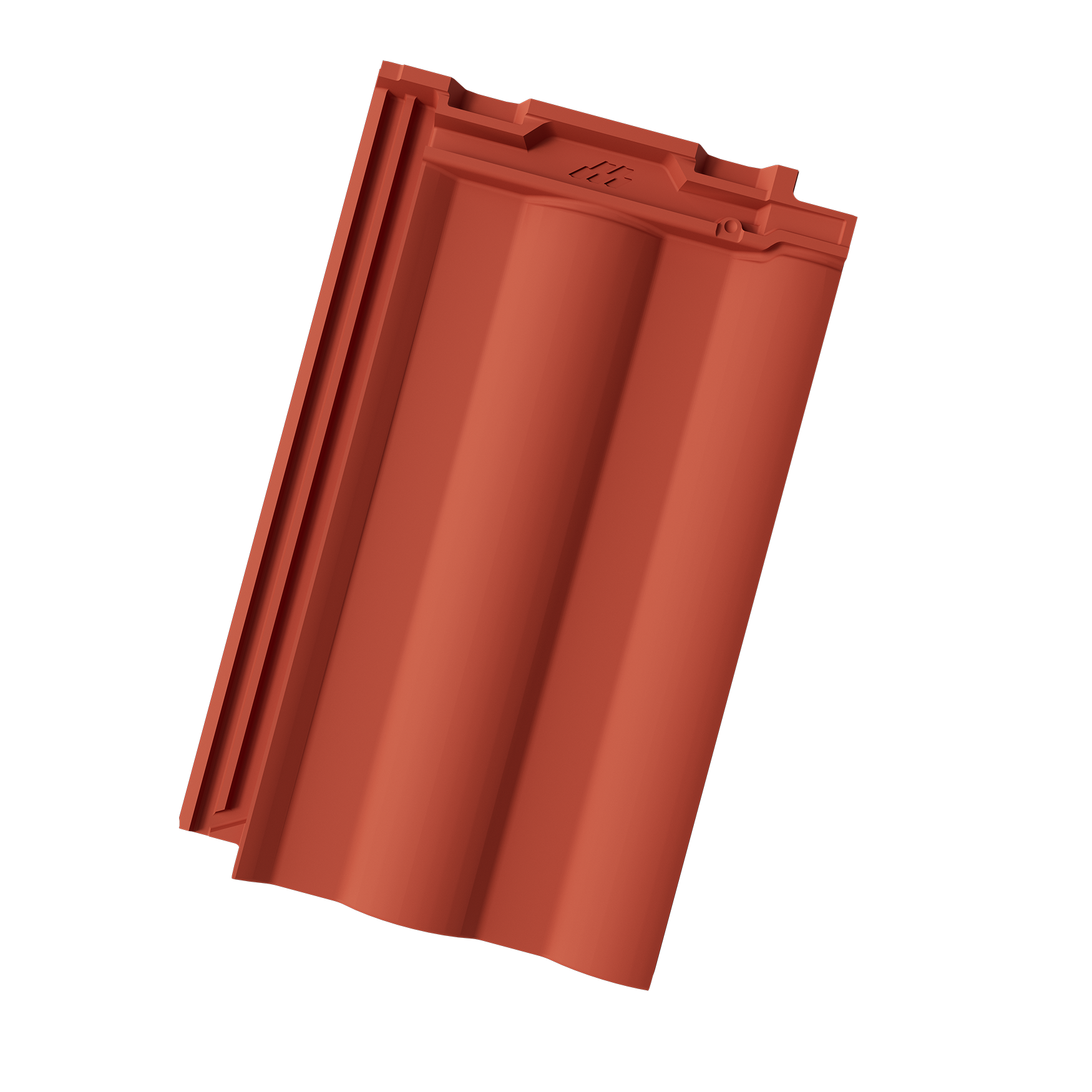

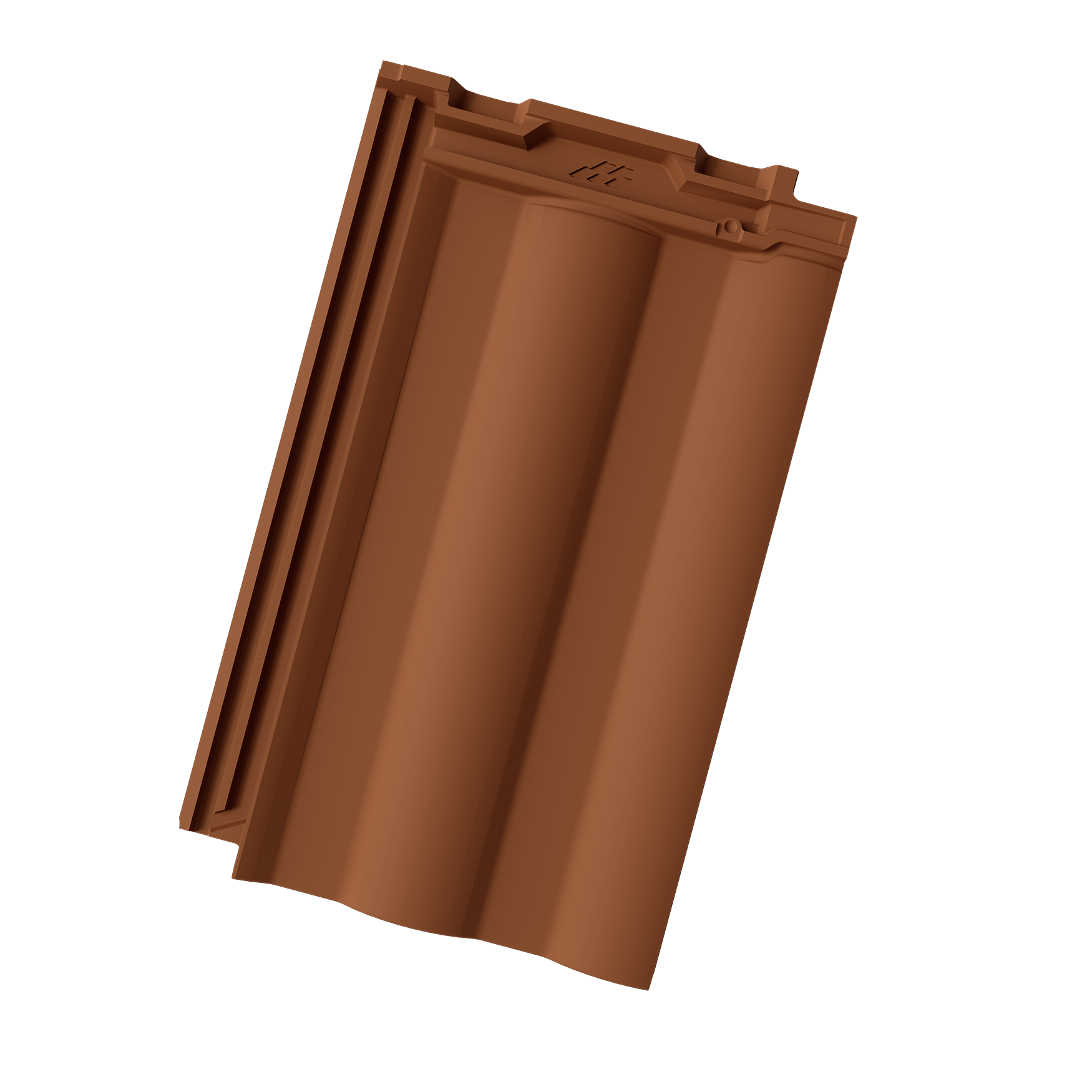

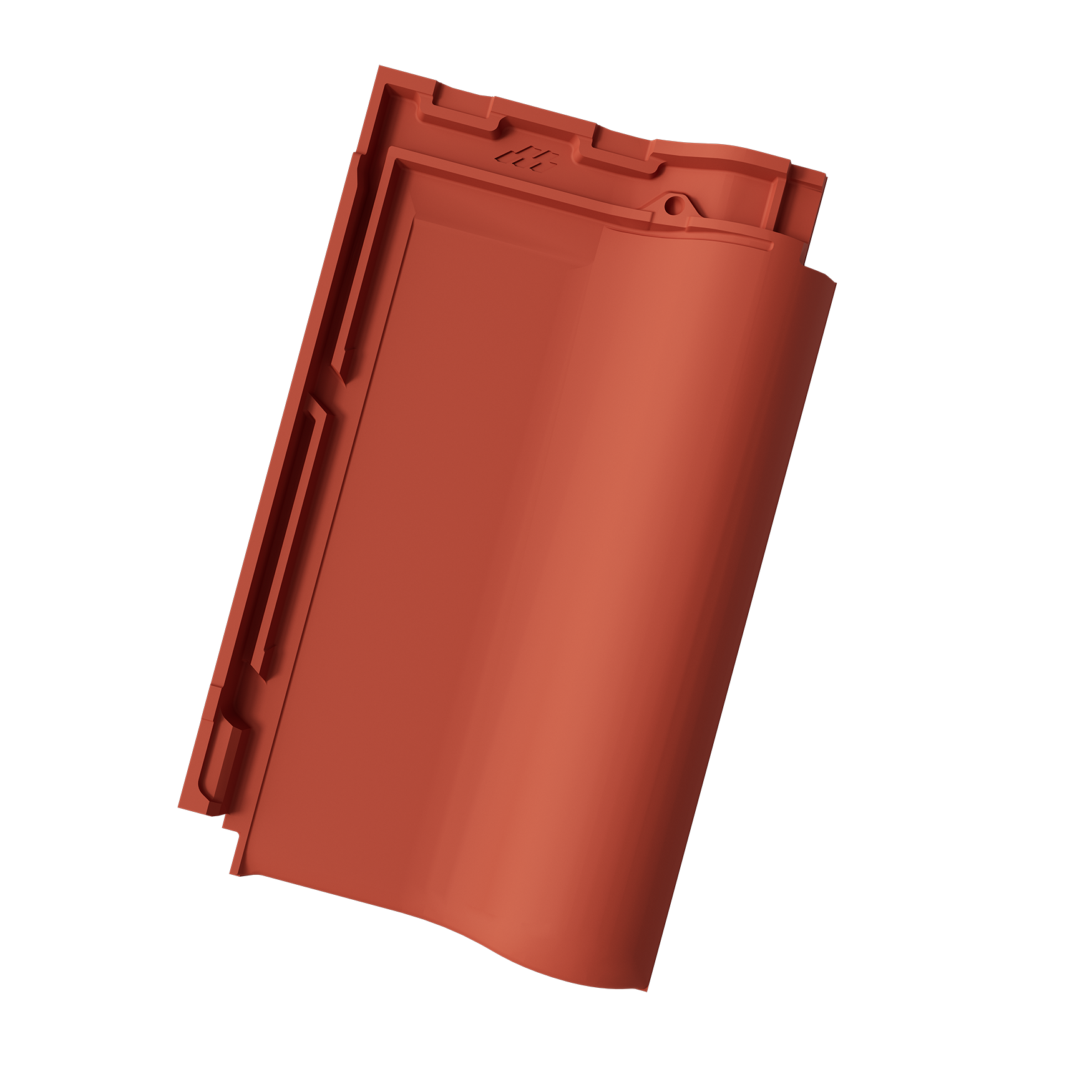

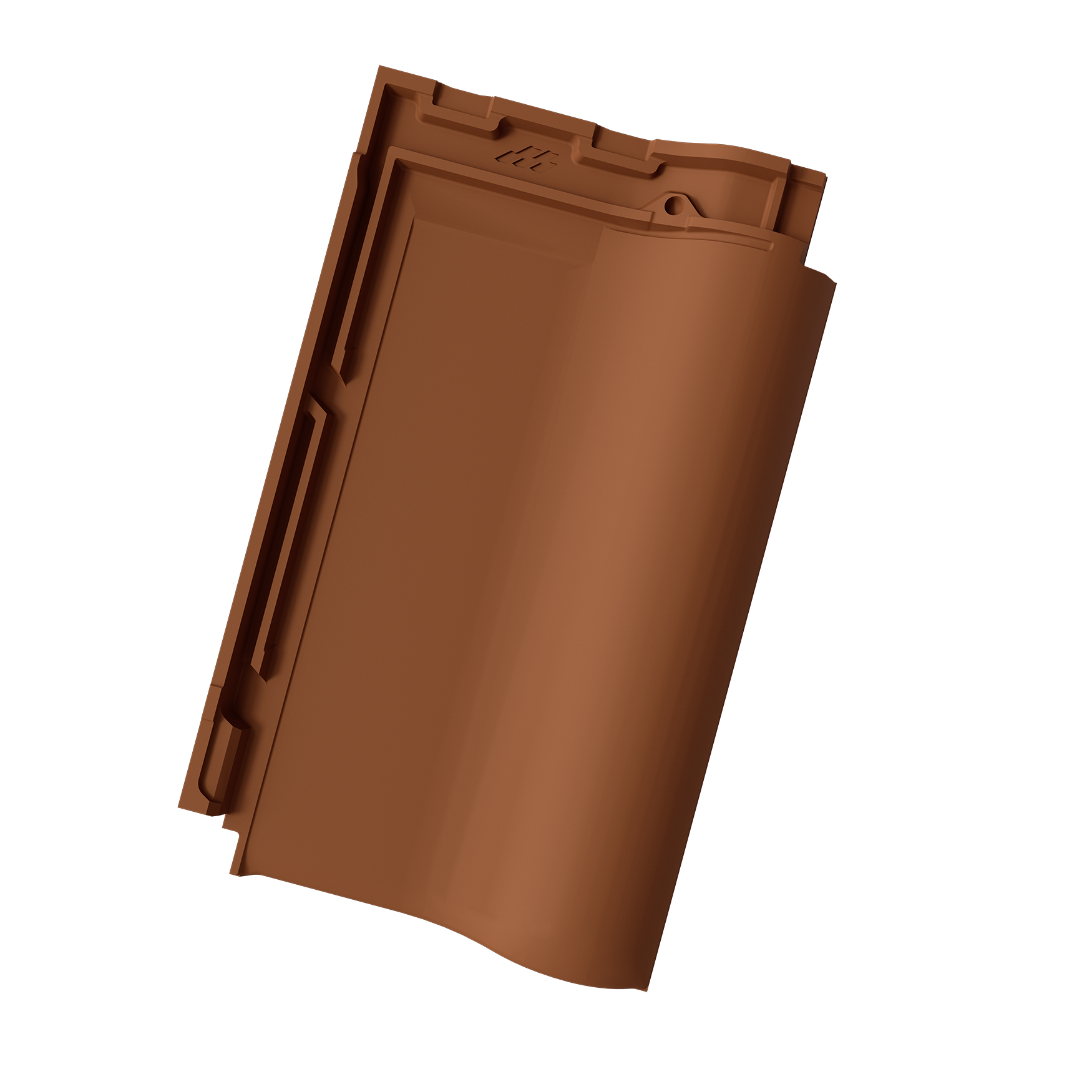

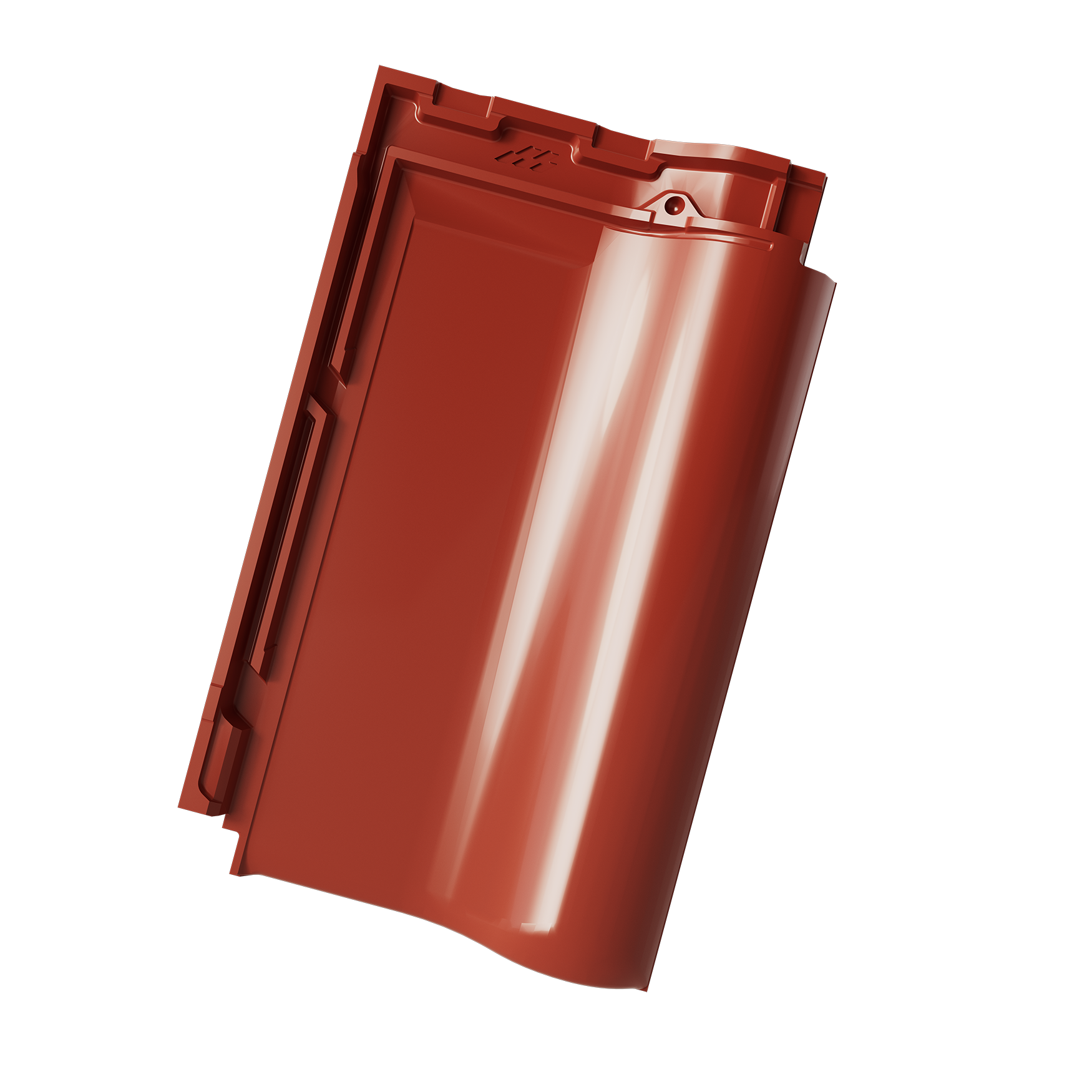

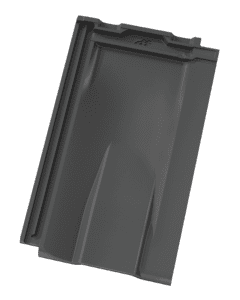

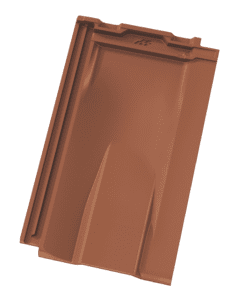

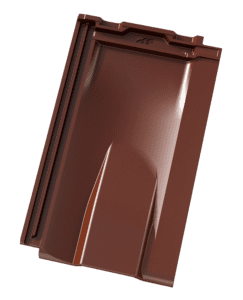

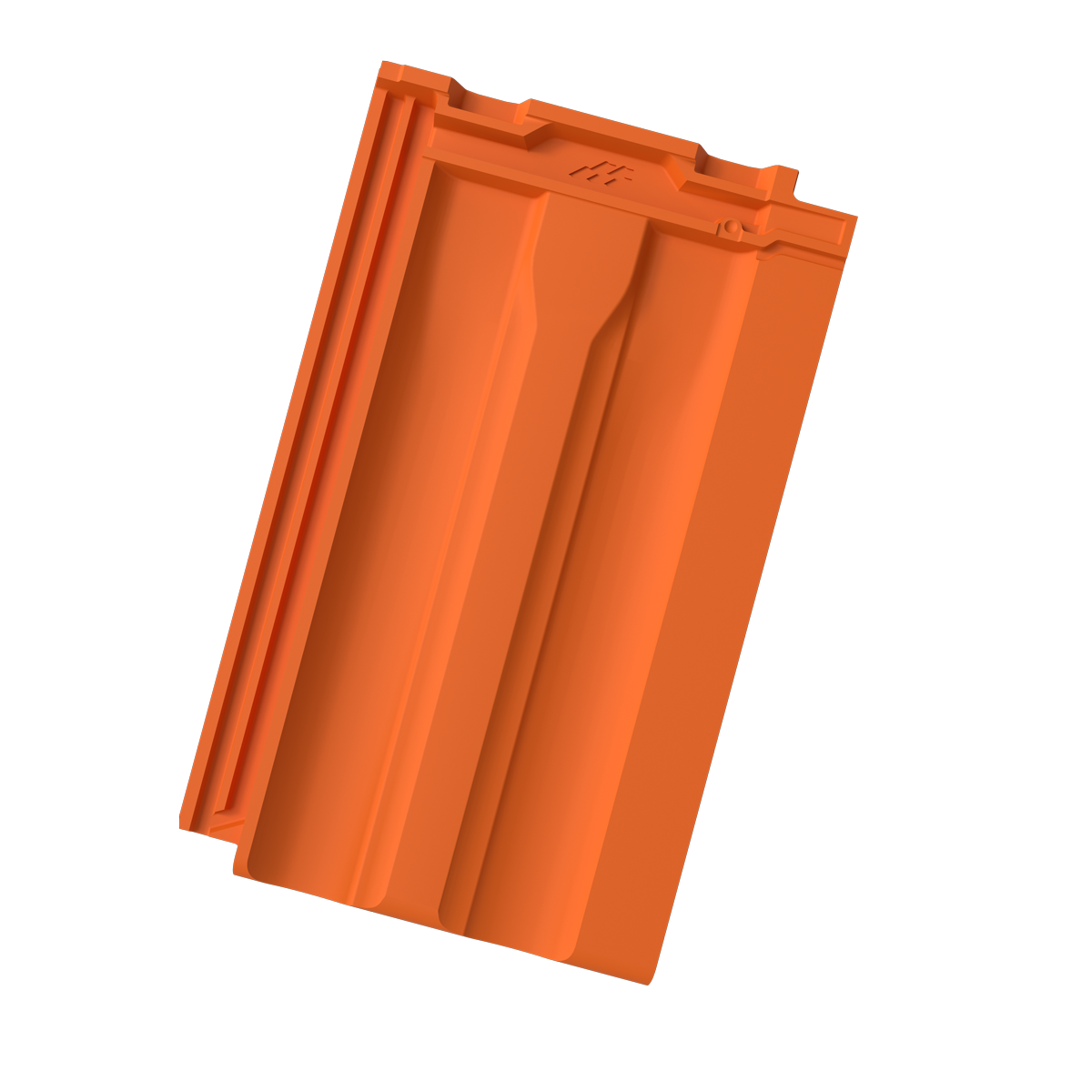

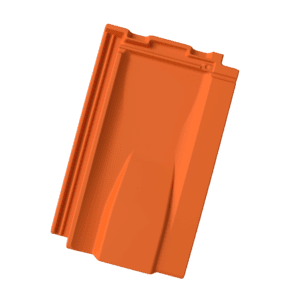

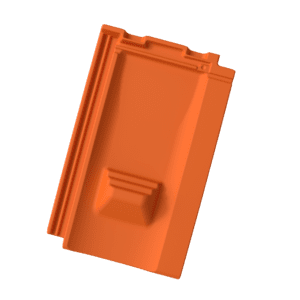

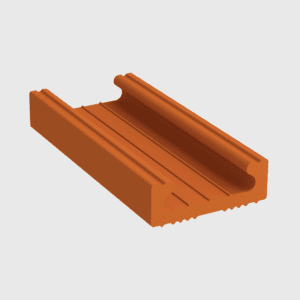

Distinctive roof tiles with an embossed elephant sign and vivid red color were created, on the foundations of an old brick factory, with a symbolic chimney that dominates Leskovac. From traditional methods to modernization in 1974, our factory strived to preserve quality and expertise at every step. A period of stability and moderate development followed until we became a joint-stock company in 2003, driven by the desire for innovation.

IGM MLADOST d.o.o. Leskovac – branch Mala Plana

From 2007 to 2010, we invested significant funds in three factories - Leskovac, Vlasotince and Mala Plana. We strived for the latest technology, infrastructure improvement, process optimization and strengthening of our human resources!

IGM MLADOST d.o.o. Leskovac – branch Vlasotince

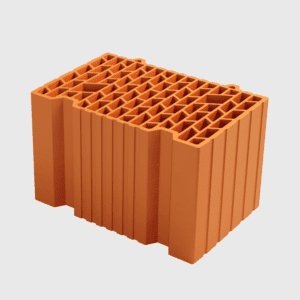

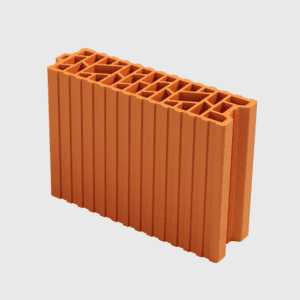

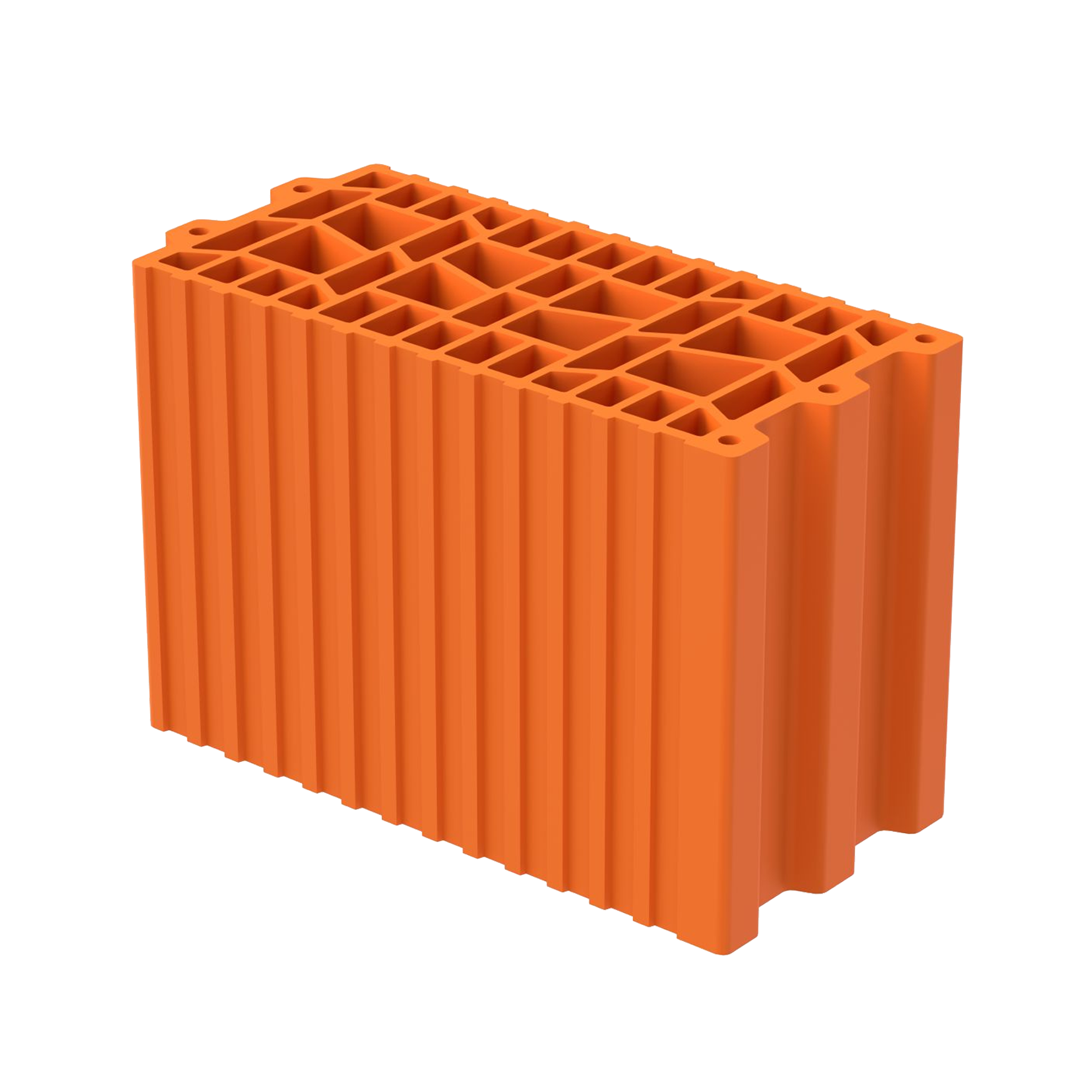

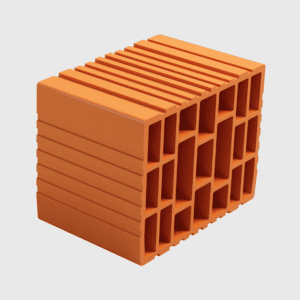

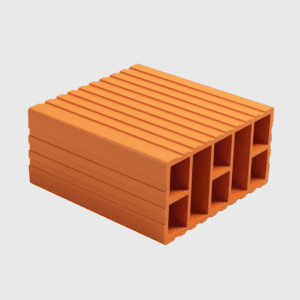

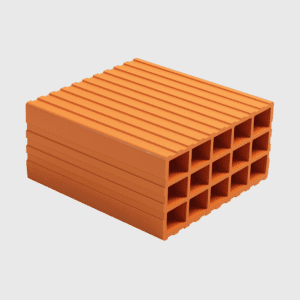

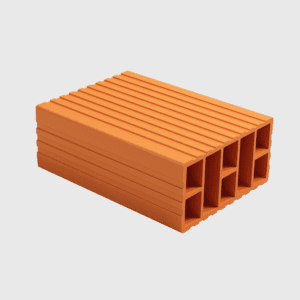

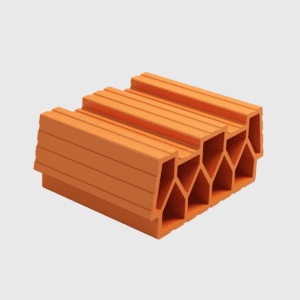

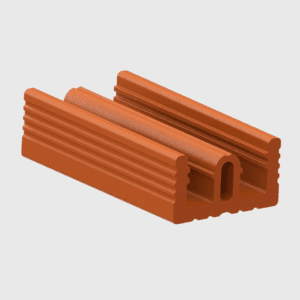

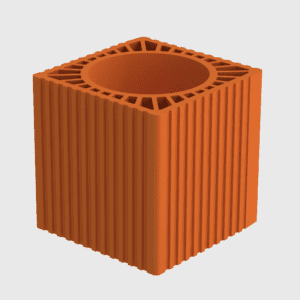

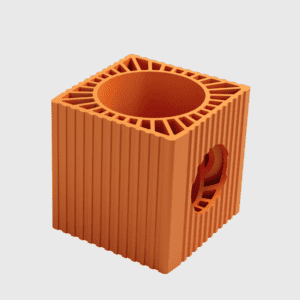

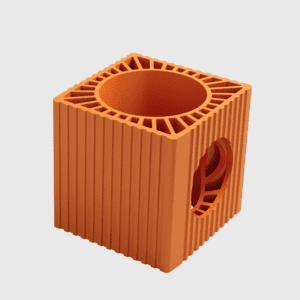

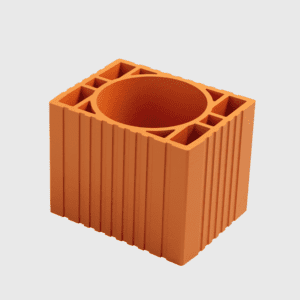

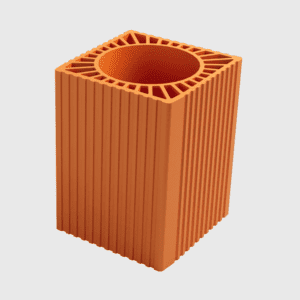

Before privatization, the factory in Vlasotince produced blocks and roof tiles for the local market. 2006 brought huge changes - privatization started a new era for us! In 2008, a reconstruction was carried out that laid the foundations for our technological progress. The factory became technically modern, automated and robotized, which allowed us to meet all market demands and customer needs. The investments were significant - a completely new production line, new mills, the latest generation press, robots and complete automation of the drying and shaping of goods. What was the result? Today, we proudly produce various types of building materials, such as giter 5, energy blocks for external and internal walls, thermoblocks of various dimensions, fert and vent blocks.

IGM MLADOST d.o.o. Leskovac – branch Stalać

With the last investment at the end of 2010 and the beginning of 2011, as well as with the reconstruction of the new factory in Stalać at the beginning of 2018, the investment cycle was crowned with the installation of key technologies that will enable a significant improvement in the quality, quantity and range of production, all with the aim of satisfying the needs of our customers.

The construction material industry IGM MLADOST unites five factories in central and southern Serbia into one recognizable name known, above all, for the quality of its products. The factory in Leskovac organizes the production of tiles, while the factories in Toplička Mala Plana, Vlasotince and Stalać produce blocks for masonry and mezzanine constructions. MLADOST bases its great reputation on over a hundred years of tradition. Namely, with the establishment of our first factory for the production of ceramic products in 1911, the foundations of the modern production of clay construction materials were laid. The tallest chimney in Leskovac is located in this factory and is a symbol of tradition and a testament to the skill, stability and beauty of architectural creation.

The Beginning of Our Success

The production of clay construction materials in the vicinity of Leskovac, Vlasotince and in the Toplica basin is as old as the presence of human communities in that area. The abundance of quality raw materials was used by the builders of the ancient empires, leaving monuments of their construction skills. At the transition between Antiquity and the Middle Ages, Carica town near Lebane, the oldest architectural monument in southern Serbia, was created. The tradition of brick production from the Byzantine era continued in the Middle Ages, in which many works of sacred architecture were created, primarily in the basin of Toplica.

The Beginning of Our Success

From those ancient times until today, there have been changes in ownership and organization, but not changes in the skill of making clay products, which, like the recognizable red color, has proven to be more durable than many social systems and epochs. Our factories in Leskovac, Vlasotince, Toplička Malá Plana and Stalać were built in the most attractive locations and on the foundations of such a long and rich tradition in the production of ceramic products.

Mladost Today

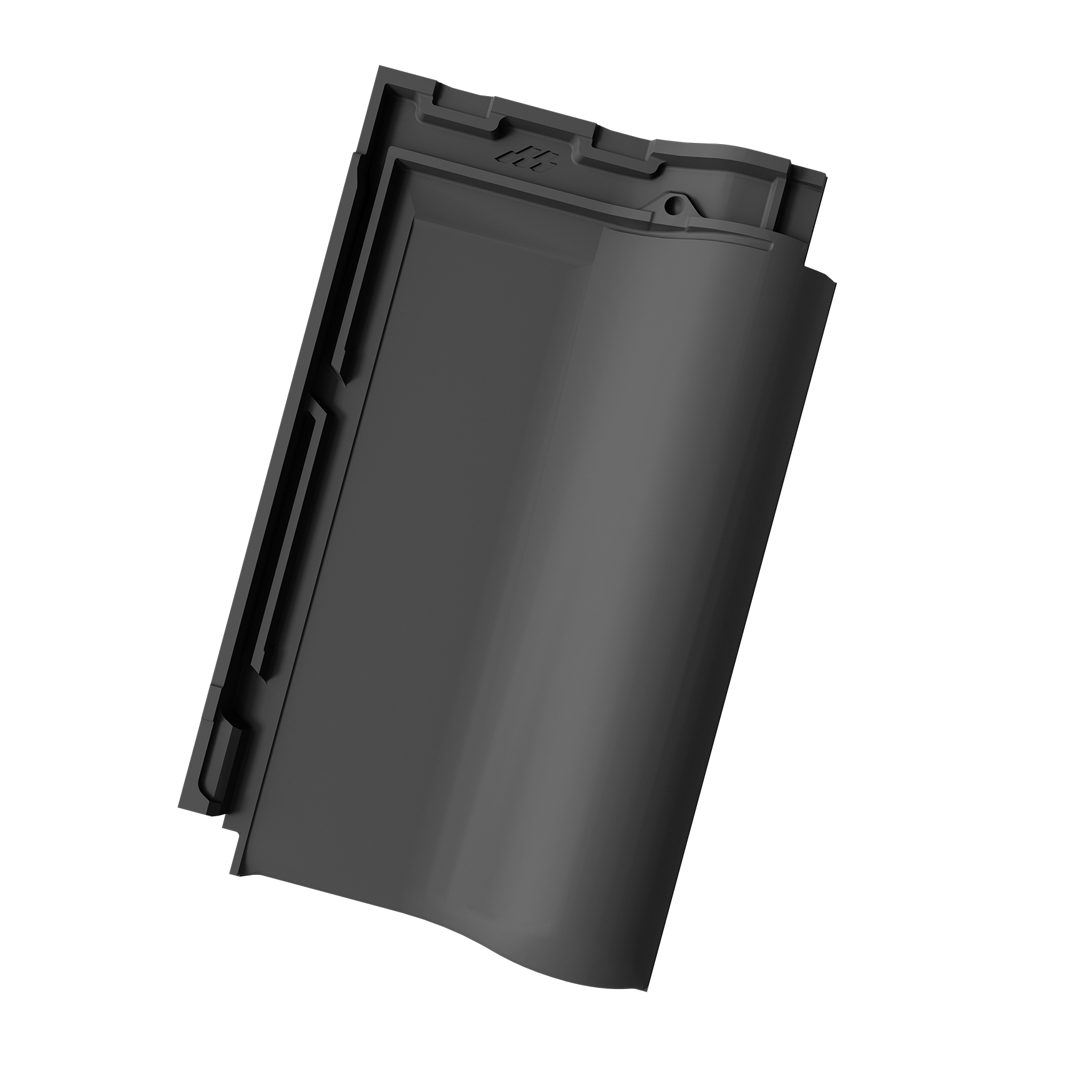

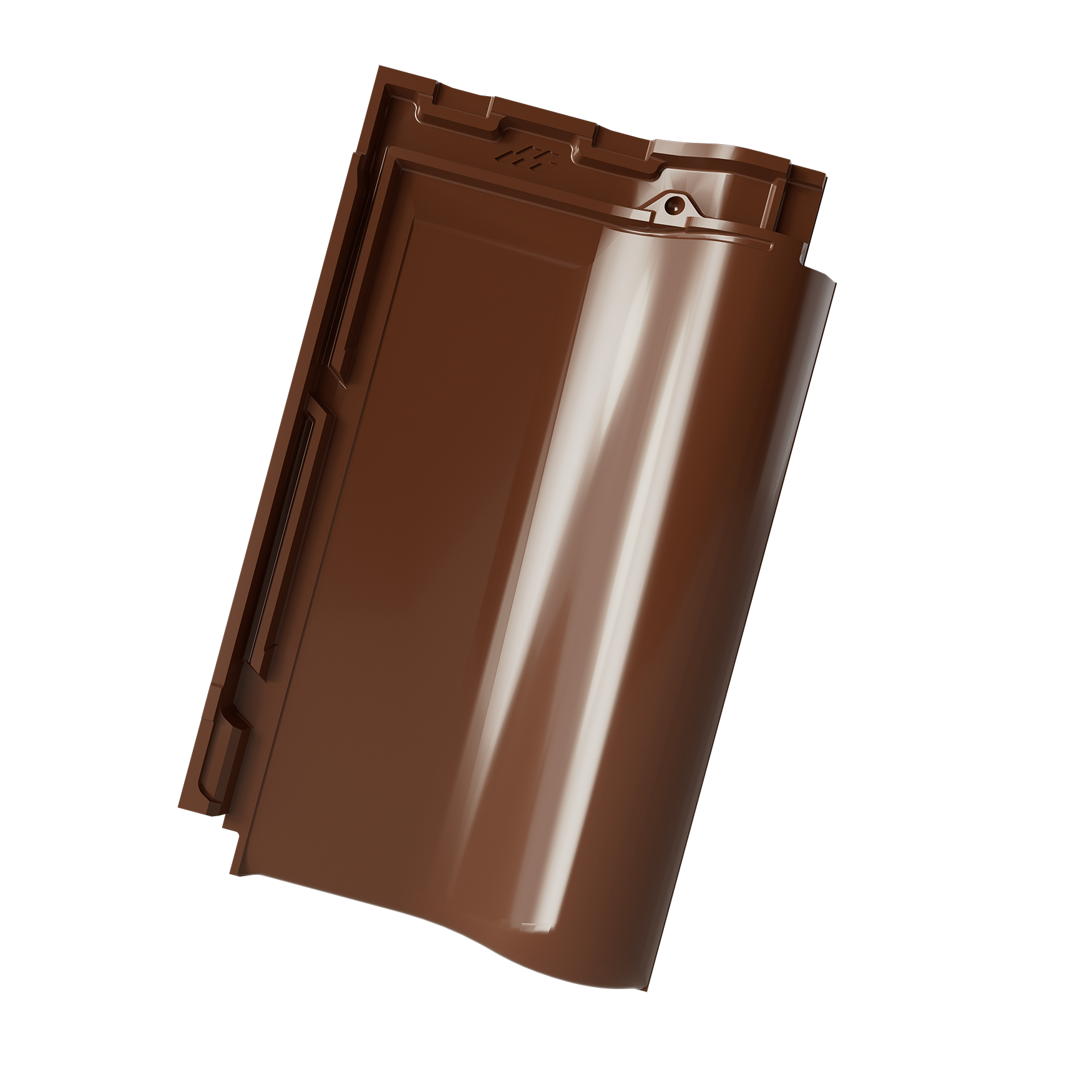

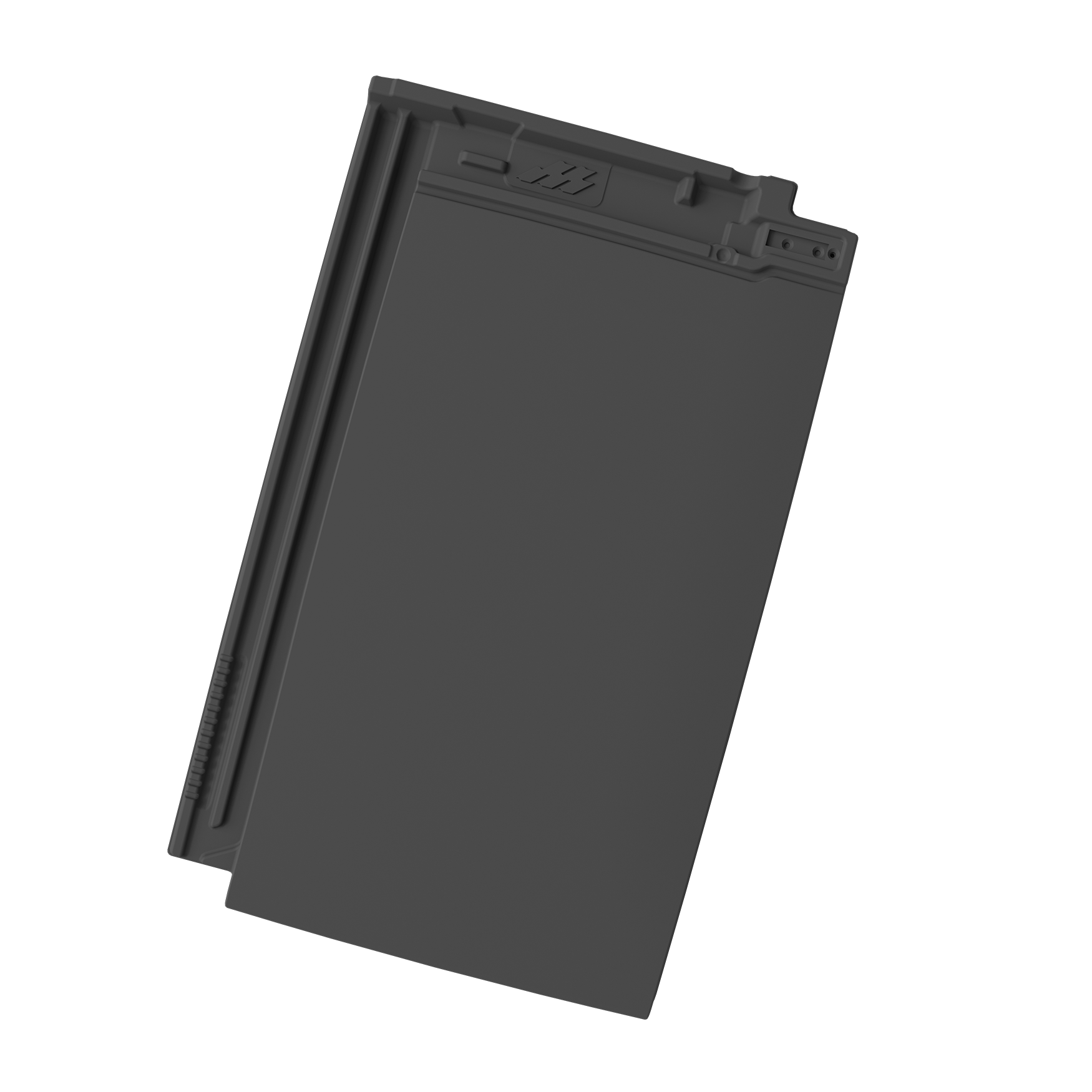

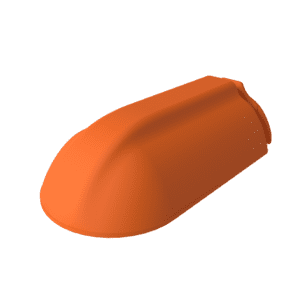

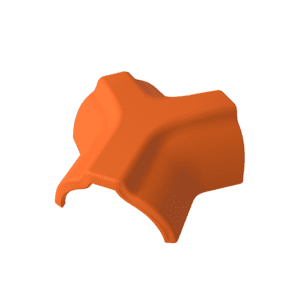

Due to the ideal mineralogical composition of the raw material, all products, in addition to their exceptional physical and mechanical characteristics, have an intense and lasting red color that distinguishes them conspicuously from all other products of this type. Due to these properties, all our products have rapidly conquered many markets. Modern construction in Serbia and the wider region is almost unimaginable today without products produced in MLADOST factories.

Mladost Today

Today, they are extremely modern factories. With large investments, the most up-to-date equipment and technology was introduced in all factories, which, together with extremely high-quality raw materials and professional workforce, enables production that meets the strictest requirements for high-quality, economical and simple construction.v

Mladost - an inherited quality

MLADOST is one of the biggest and most prominent producers of construction materials in the Balkans and Southeastern Europe. It is a synonym for high-quality roof tiles, building blocks and mezzanine constructions. MLADOST – a system for modern construction!

Here’s how we started…

IGM MLADOST Leskovac

1911

1911 – with the foundation of the "Keramička fabrika Rafajlović, Sokolović and Bejaž", the foundations of the modern clay construction material industry were laid. The huge building of the so-called "old brick factory" with the highest chimney in Leskovac is still one of the symbols of the city. The tiles that were produced in Leskovac at the beginning of the last century, with an embossed elephant sign and its distinctive, intense red color, still adorn the roofs of Leskovac, Niš, Vranje, Skoplje and many nearby and distant cities.

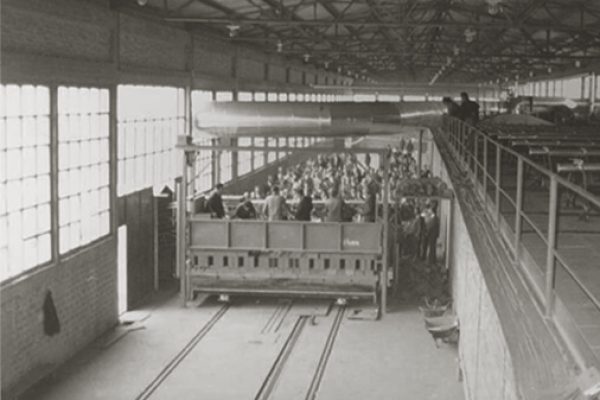

Traditional methods of shaping clay were applied until 1974, when a new hall was built with devices and machines for the production of tiles and blocks, modern for that period of history. However, certain segments of production at that time were still based on manual work and the use of a large number of workers, without a detailed consideration of the possibility of increasing the quality and quantity of production.

IGM MLADOST Leskovac

DP Pobeda

1928 – with the resignation of one of the owners, Mihajlo Sokolović, the factory was given the new name "Keramička fabrika Rafajlović i Bejaž". After the Second World War, the factory grew into DP "Pobeda" - an industrial company of tiles and bricks, whose products would be known throughout the old Yugoslavia.

IGM MLADOST Leskovac

DP Mladost

1997 – the company was divided into several smaller ones, specialized in the production of certain types of construction materials. This is how D.P. "MLADOST" was created as a group of young, hardworking and motivated people, who want to return to their old markets and present themselves in new ones. The period that followed was marked by stability in business and moderate development, in accordance with the general circumstances in society. 2003 – with the privatization, the company MLADOST becomes a joint-stock company, and the management and employees receive a new incentive for further improvement and development. From that moment until 2008, they worked on constantly increasing the quality and capacity of production, and the company IGM MLADOST completely reoriented itself to the production of tiles. In the same period, the company used the time for employment and professional development of new personnel of basic production profiles: technology, mechanical engineering and electronics.

IGM MLADOST Leskovac

FACTORY GROWTH and DEVELOPMENT

2008 – a new period begins with the reconstruction of the factory, which represents an important step in modernizing the production process, especially in the part of primary processing, with the introduction of state-of-the-art mills with a large capacity for fine processing of clay, as well as great progress in stacking and disassembling dry and baked goods, especially in terms of packaging products with full process automation. Moreover, during the first phase of the reconstruction, great emphasis was placed on modernizing and automating the process of drying and baking products, with the most modern systems for monitoring and controlling the quality of the process. In addition, it greatly contributed to the increase in the quality of working conditions and the humanization of work.

IGM MLADOST Leskovac

FACTORY GROWTH and DEVELOPMENT

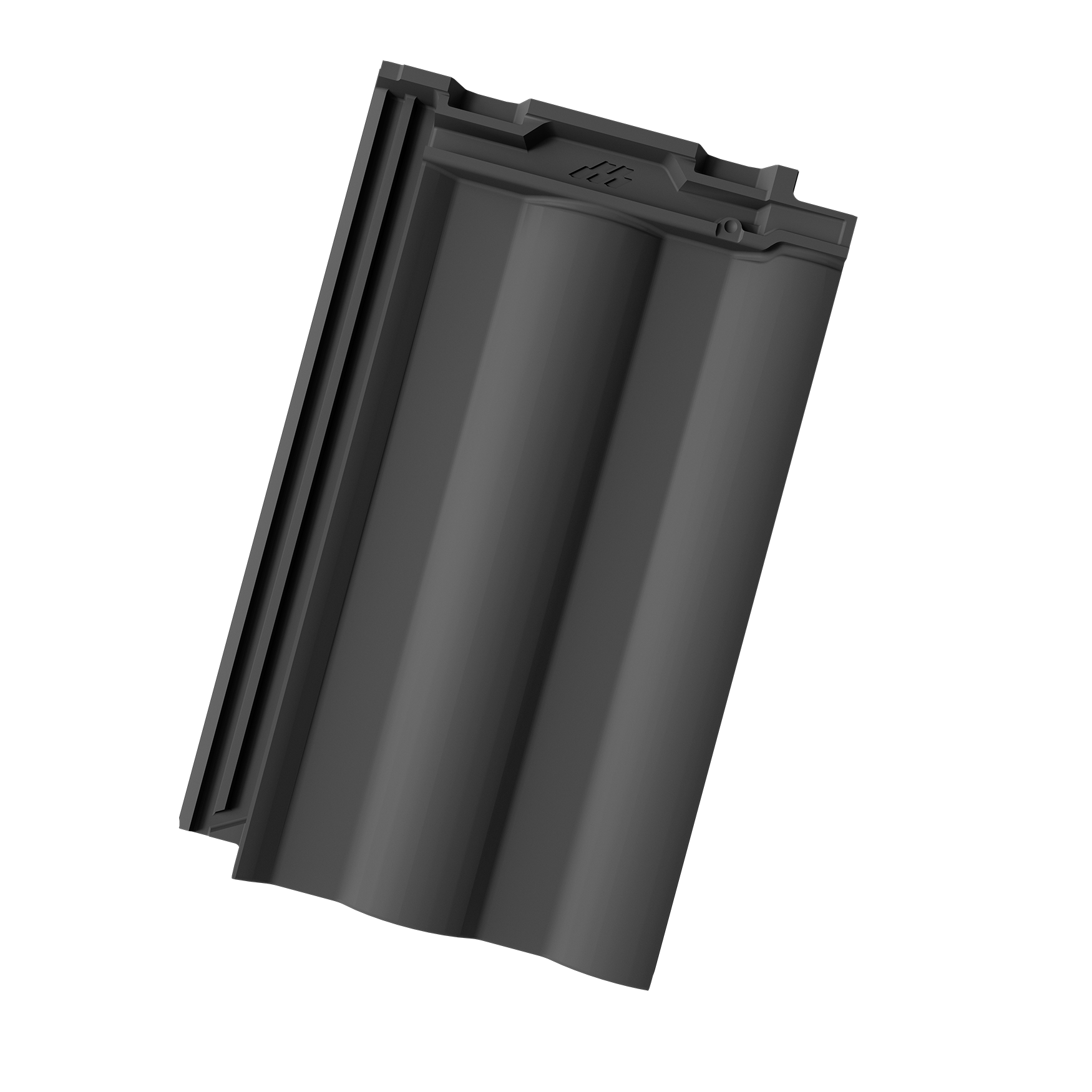

2011 – the second part of this reconstruction with the extension of the production hall of raw production, which is based on the installation of a new extruder from the German manufacturer "Händle" and the installation of new double-head presses from the Italian company "Bongioanni", which are among the most modern in this field. The application of this modern and highly controlled technology directly affects the quality of the product in terms of physical and mechanical characteristics, as well as the aesthetic appearance of the tiles, which satisfies the demands of an increasingly discerning market.

IGM Mladost Mala Plana

2006 – the privatization of the IGM "7. JULI" in the Toplička Mala Plana town, which until then operated as a social enterprise. Since that day, the factory has been operating under the name IGM "MLADOST-TMP" doo. Immediately after privatization, already in 2006, the reconstruction of the factory began: in 2007, a fully automatic product stacking and sorting line was installed; a brand new fine mill of a renowned German manufacturer Haendla was installed; the furnace was reconstructed and new burner groups were installed. A system for monitoring the temperature and other parameters in the furnace and dryer, 6 fan groups for the dryer, a high-pressure compressor and a new compressed air distribution network were installed. A new production hall was also built to accommodate the equipment for product breakdown.

IGM Mladost Mala Plana

2008 – the molding line was reconstructed, the press was converted to a system with two outputs, and the appropriate automation was installed for loading raw products onto the dryer wagons. The number of ventilation groups in the dryer was increased and the complete line of forming, loading of raw goods and unloading of dry goods was automated. A wheel mill with a larger capacity was installed, followed by another high-pressure compressor and a new 630 kW transformer.

IGM Mladost Mala Plana

2009-2010 – the following equipment was installed: coarse Bedeschi mill, Bedeschi extruder, flue gas fan, flue gas recirculation system on the furnace. Reconstruction of the primary processing was carried out.

All these investments and technical technological interventions have enabled the production of extremely high-quality products with a simultaneous increase in capacity, which is why IGM MLADOST-TMP is counted among the largest producers of blocks in Serbia.

IGM Mladost Mala Plana

2010 - a new mine of high-quality clay was opened, which allows proper access to exploitation with a suitable access road for smooth transport. A new fuel oil tank of 1,000 m3 was built and 10,000 m3 of space for storing finished products was paved; a new administrative building was built, the premises of the technical services were renovated and a restaurant for the food of the workers inside the production hall.

IGM Mladost Vlasotince

The IGM "RAD" factory in Vlasotinac operated as a social enterprise until November 6, 2006.when the privatization took place, and since that day the factory has been operating under the name IGM "MLADOST RAD" AD.

In the period before privatization, the factory produced blocks (about 5,500,000 pieces annually) and roof tiles (about 2,000,000 pieces), which it mainly sold on the local market.

2007 – preparations for the reconstruction of the factory begin, with the aim of improving production and significantly modernizing it.

2008 – reconstruction completed

IGM Mladost Vlasotince

2009 – start of production using new technology.

With this reconstruction, the factory became technologically modern, automated and robotic, which was a requirement for the production of building materials in accordance with market requirements and customer needs.

Specific investment projects were: a completely new production line, new primary and secondary processing mills from the manufacturer "BONGIOANNI", the latest generation press from the manufacturer "BEDESCHI", the latest generation robots from the Japanese manufacturer "FANUK", a fully automated process of the raw forming line, dry stacking of goods on wagons and a line for breaking down baked products, completely reconstructed and modernized dryers.

IGM Mladost Stalać

The company "Vojvoda Prijezda" Stalać has been operating since 1948, which is also the year when the production of brick products officially began. The main activity of the company is the production and delivery of building materials (clay bricks and tiles). In the period from 1948, when the company started working, until 2006, when it was registered as the Joint Stock Company "Vojvoda Prijezda" for the production and sale of construction materials Stalać, the following organizational and status changes took place: • The company was independent until 1953, but in the mentioned year it became part of the company "Dušan Ristić" from Kruševac, where it operates as a work unit. • In 1973, the company became OOUR "Stalać" within RO "Dušan Ristić" from Kruševac. • In 1989, the company separated from RO "Dušan Ristić" from Kruševac and since then has been operating under the name.

IGM Mladost Stalać

Joint Stock Company "Vojvoda Prijezda", Stalać as a separate legal entity. • In 2002, by decision of the Commercial Court in Kraljevo, and to harmonize its activities with the Act on the Classification of Activities, the company operates under the name Social enterprise for the production and sale of construction materials "Vojvoda Prijezda", Stalać. • 2005 By auction sale on October 6, 2005, the company changes its form of ownership and transfers to Joint Stock Company "Vojvoda Prijezda" with 70% of the sold capital. • In 2007, according to the request for forced sale, "Mašinac" doo Kraljevo bought the remaining 30% of the capital. The main activity of the company is the production and sale of construction materials and the company is registered for the performance of other activities, which are listed in the court register, as well as for foreign trade activities performed within the registered activity of wholesale trade. On June 6, 2017 "Vojvoda Prijezda" was bought from bankruptcy by the company "Mladost" Leskovac and until December 31, 2023 it operates independently under the name "Mladost".

IGM Mladost Stalać

"Vojvoda Prijezda" Stalać merged with the company "Mladost" doo Leskovac as Branch Stalać, according to the Decision on merging from January 1, 2018. The reconstruction of the factory started on August 31, 2017, in all units, and production started on March 19, 2018. They spent the entire 2018 and 2019 on investment and increasing production capacity. Today, the Stalać production plant produces a wide range of Mladost energy blocks, thermoblocks and standard blocks. Using the most modern technology and the knowledge of the best experts in the field, Mladost energy clay blocks enable the energy efficiency of the facilities in which they are installed. They are a modern and ecological solution that guarantees durability and longevity, a healthy spatial microclimate and a safe home for future generations.

Our factories use extremely high-quality clay that was tested by the Institute of materials and structures from Belgrade.

EXTRACT FROM A SCIENTIFIC PAPER

“ASSESSMENT OF THE QUALITY OF BRICK RAW MATERIALS FROM THE SOUTH OF SERBIA” Zagorka Radojević, Ph.D., Milica Arsenović, Ph.D., Miloš Vasić, Ph.D.

The paper presents the results of research into the quality of three brick raw materials from the south of Serbia: from the deposit near Leskovac, from the deposit near Vlasotince and the deposit near Mala Plana. The research included chemical, mineralogical, granulometric and ceramic-technological characteristics of representative samples from the mentioned deposits. The paper also provides an assessment of raw materials from the aspect of the quality of brick products, energy efficiency and ecological parameters.

INTRODUCTION

The basic raw materials for the production of brick products are clay, loess, clay, marl, etc. Geological research and testing of raw materials in Serbia are carried out in a unique way. These researches are carried out according to generally valid methods and regulations, which provide sufficient data on the quality and quantity of raw materials and on the basis of which the decision on exploitation is made. There is no building material that could replace brick products in terms of strength, porosity, insulating abilities, durability, fire safety, resistance to weathering and corrosion, stability of form and the possibility to achieve diversity in construction. In addition to the mentioned positive properties of this building material, the production and use of brick products is also driven by the increasingly urgent need to preserve the environment, and thus the preservation of living, working and health conditions for people. The south of Serbia has a developed production of various assortments of brick products. Modern highly automated technological lines were put into operation in the plants for the production of brick products: “MLADOST” doo – Leskovac, “MLADOST-RAD” doo – Vlasotince and “MLADOST-TMP” – Mala Plana. Their work is based on a high-quality local raw material base. The paper evaluates the raw materials from the aspect of product quality, energy efficiency and ecological parameters.

QUALITY OF BRICK PRODUCTS

Based on the results of the examination of brick raw materials from the south of Serbia, it can be concluded that modern production can produce: Brick products of a wide range (tiles, facade bricks and blocks, brick products for interior walls, ceiling elements, porous brick products, etc.)

Products with high aesthetic properties, intense red color,

Products without salt efflorescence and defects of the action of lime,

Products with high mechanical characteristics (compressive and flexural strength),

Products that provide good fire resistance and excellent thermal and acoustic properties of facilities.

The color of baked brick products basically depends on the mineralogical composition of the raw material, temperature and baking conditions. Iron has a dominant influence on the color of brick products. Brick raw materials contain iron mainly in the form of minerals from the hydroxide group (goethite, limonite). During the firing process, iron hydroxide is transformed into hematite, which gives the ceramic body a red color. From the test results, it can be concluded that the color of the baked products is intensely red.

A low content or absence of carbonates indicates the absence of harmful effects of lime on baked products.

The mechanical characteristics of baked products are high.

ENERGETIC EFFICIENCY

The results of testing the ceramic-technological characteristics of the samples indicate that the required firing temperature is relatively low, 830-9000 °C . The low firing temperature significantly lowers the specific energy consumption in the firing process and increases the energy efficiency of the process. For the sake of comparison, the most often required firing temperature for brick products in plants in Serbia is in the interval 950-10500 °C . The good plasticity of the examined samples enables the production of brick products with thinner walls, i.e. less mass, which reduces the consumption of raw materials and energy consumption per unit of normal format.

ECOLOGICAL ASPECT

Avoiding environmental pollution is placed before modern production processes. The production of brick products allows the use of waste materials. Tested raw materials can be mixed with waste materials while designing optimal mixtures for a certain type of product. Emission of gases in the firing process comes from fuel and raw materials. This is how HF, SO3, SO2, HCl, CO2 and others appear. This issue requires serious studies of the overall emission and the necessary measures.

However, based on the results of the examination of the chemical composition of raw materials from the south of Serbia, there are no conditions for a significant emission, because the content of components that emit harmful gases in the baking process is minimal or absent. Even the carbonate content in the raw material is low, so there is almost no CO2 emission coming from the raw material.

CONCLUSION

Brick raw materials from the south of Serbia represented by the tested samples represent a significant raw material base for the production of various product ranges, with high aesthetic and physical-mechanical characteristics. The properties of the raw materials enable energy-efficient production in modern plants. Raw materials can be considered high-quality from the point of view of increasingly strict environmental requirements.